- 30a Muriel Brand Str, Brenthurst, Brakpan

- sale@feelinhomey.com

- 011-740-6583

- 073-246-9457

2026 Top Trends in Empty Storage Containers for Efficient Logistics Solutions?

As global trade evolves, the role of empty storage containers is becoming increasingly significant. Efficient logistics solutions hinge on optimizing these containers. Their proper management can lead to substantial cost savings and enhanced supply chain performance. These units, once overlooked, hold potential beyond mere storage.

Empty storage containers present unique challenges. They occupy valuable space in ports and warehouses. This issue demands innovative strategies to streamline logistics. Companies must rethink their approach to these containers. Leveraging technology, such as tracking systems, helps manage empty containers efficiently. Yet, improvements are still needed. Not all businesses embrace these advancements fully.

In the quest for efficiency, it’s crucial to consider sustainability. There’s a growing need for eco-friendly practices in using empty storage containers. However, misconceptions around their reuse often arise. Many overlook the benefits of recycling and repurposing. A shift in mindset is essential to realize their full potential in logistics.

2026 Predictions for the Empty Storage Container Market Dynamics

The empty storage container market is evolving rapidly. By 2026, we can expect notable changes driven by supply chain needs. Companies face pressures to optimize logistics. As a result, empty container management will become crucial for efficiency.

Sustainability will play a key role in shaping market dynamics. More firms will explore eco-friendly storage solutions. Innovations in materials and design will emerge. On the other hand, companies may struggle to balance cost and sustainability. It’s a complex decision-making process.

Technology will further transform the sector. Advanced tracking systems will allow real-time monitoring of storage containers. This will enhance efficiency in logistics. However, there may be challenges. Not all companies can adopt these technologies at the same pace. Trust and data security remain pressing issues.

Innovative Technologies Enhancing Empty Container Management Efficiency

In 2026, innovative technologies are set to revolutionize empty container management, enhancing logistics efficiency. For instance, advanced tracking systems can reduce the time containers sit idle. According to a recent industry report, inefficiencies in container usage can lead to losses of up to 20% in logistics costs. Embracing IoT technologies allows for real-time data collection, enabling quicker decision-making.

Tips: Implementing predictive analytics can help businesses anticipate empty container demand. This may lead to better utilization rates. Automated systems can also streamline inventory management, but companies must ensure staff receive adequate training.

Moreover, AI algorithms can optimize routing for empty containers. This reduces transportation costs and environmental impact. However, relying solely on technology can lead to operational blind spots. It's essential to balance digital solutions with human oversight for effective management. As the industry evolves, the challenge lies in adapting to these changes while remaining efficient.

2026 Top Trends in Empty Storage Containers for Efficient Logistics Solutions

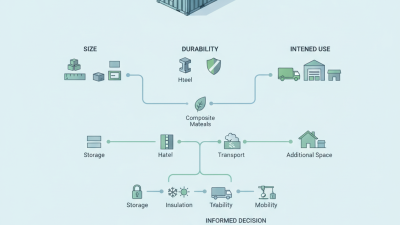

The chart below illustrates the top trends in empty storage container management for 2026. The data highlights the increasing adoption of innovative technologies aimed at enhancing efficiency in logistics.

Sustainability Trends Shaping the Future of Empty Storage Solutions

Sustainability is becoming essential for the logistics sector. As more companies focus on eco-friendly practices, empty storage containers hold great potential. Their role in reducing waste is crucial. Using these containers wisely can significantly minimize environmental impact.

Many businesses are exploring alternative materials. Biodegradable and recyclable options are emerging. This trend shows promise, but it requires careful implementation. Investing in durable and reusable containers can lead to long-term benefits. Keep in mind, though, that not all options are created equal. Some claims may be exaggerated.

Tips: Regularly assess your storage containers. Check for wear and tear. This can prolong their lifespan. Consider collaborating with local suppliers. Supporting nearby businesses often reduces transportation emissions. Pack smarter, not harder. Efficient packing methods save space and resources. Always analyze the impact of your choices.

2026 Top Trends in Empty Storage Containers for Efficient Logistics Solutions

| Trend | Description | Impact on Sustainability | Implementation Year |

|---|---|---|---|

| Smart Container Tracking | Integration of IoT technology to monitor location and conditions of containers. | Reduces waste and maximizes resource use. | 2026 |

| Modular Container Designs | Containers designed to stack and connect, providing versatility. | Optimizes space and reduces emissions during transport. | 2025 |

| Recyclable Materials | Containers made from 100% recyclable materials. | Minimizes environmental footprint. | 2026 |

| Energy-Efficient Processes | Adoption of energy-efficient methods for container production and transportation. | Significantly lowers carbon emissions. | 2025 |

| Automation and AI | Use of automation and AI for enhanced logistics efficiency. | Reduction in human error, leading to more efficient use of resources. | 2026 |

Impact of E-commerce Growth on Empty Container Logistics Strategies

The rapid growth of e-commerce is reshaping logistics strategies for empty storage containers. As online retail expands, the need for efficient container management becomes crucial. According to a recent industry report, e-commerce sales are projected to hit $6.5 trillion by 2024. This surge significantly impacts how empty containers are utilized and repositioned.

Empty container logistics must be agile. Companies are pivoting from traditional methods to embrace technology. Data analytics helps in predicting demand patterns. In 2023, 65% of logistics firms reported using data-driven strategies for container management. This shift reduces costs and increases efficiency, but implementing such systems can be complex and requires ongoing adjustments.

Tips for enhancing container logistics: streamline communication across departments. Real-time tracking systems can improve visibility. Also, consider collaborating with other companies for shared container management. These strategies can help optimize the use of empty containers. Reflect on your current processes. Is there room for improvement? Adapting to the e-commerce boom is essential for staying competitive.

Best Practices for Maximizing Space Utilization in Storage Containers

Maximizing space in empty storage containers is crucial for efficient logistics. One effective method is stacking containers. However, improper stacking can lead to instability. Care must be taken to balance weight and avoid injuries.

Another best practice involves the use of interior organization tools. These can transform a chaotic space into a well-organized system. Shelves, dividers, and bins can segment different items. Yet, relying too heavily on organization tools may backfire. Over-complication can make retrieval cumbersome.

Regular audits are essential. Maintaining order and cleanliness is a continuous task. Containers should be inspected frequently to assess space utilization. Neglecting this can lead to wasted opportunities. An efficient system thrives on ongoing refinement, not just initial setup.

Related Posts

-

Maximize Your Space: Innovative Uses for Self Storage Containers You Never Considered

-

How Shipping Container Delivery Transforms Global Trade and Eco-Friendly Shipping Practices

-

Best 8x10 Shipping Container Options for Your Storage Needs

-

Top 10 Benefits of Using Shipping Container Storage for Your Business Needs

-

How to Choose the Best Small Shipping Containers for Your Needs

-

10 Best Container Workshop Ideas for Maximizing Space and Creativity